SGB BrandSafway’s extensive, international experience has enabled us to develop a range of specialist industrial services and fabric maintenance solutions to meet the individual requirements and minimise maintenance costs of each plant and facility.

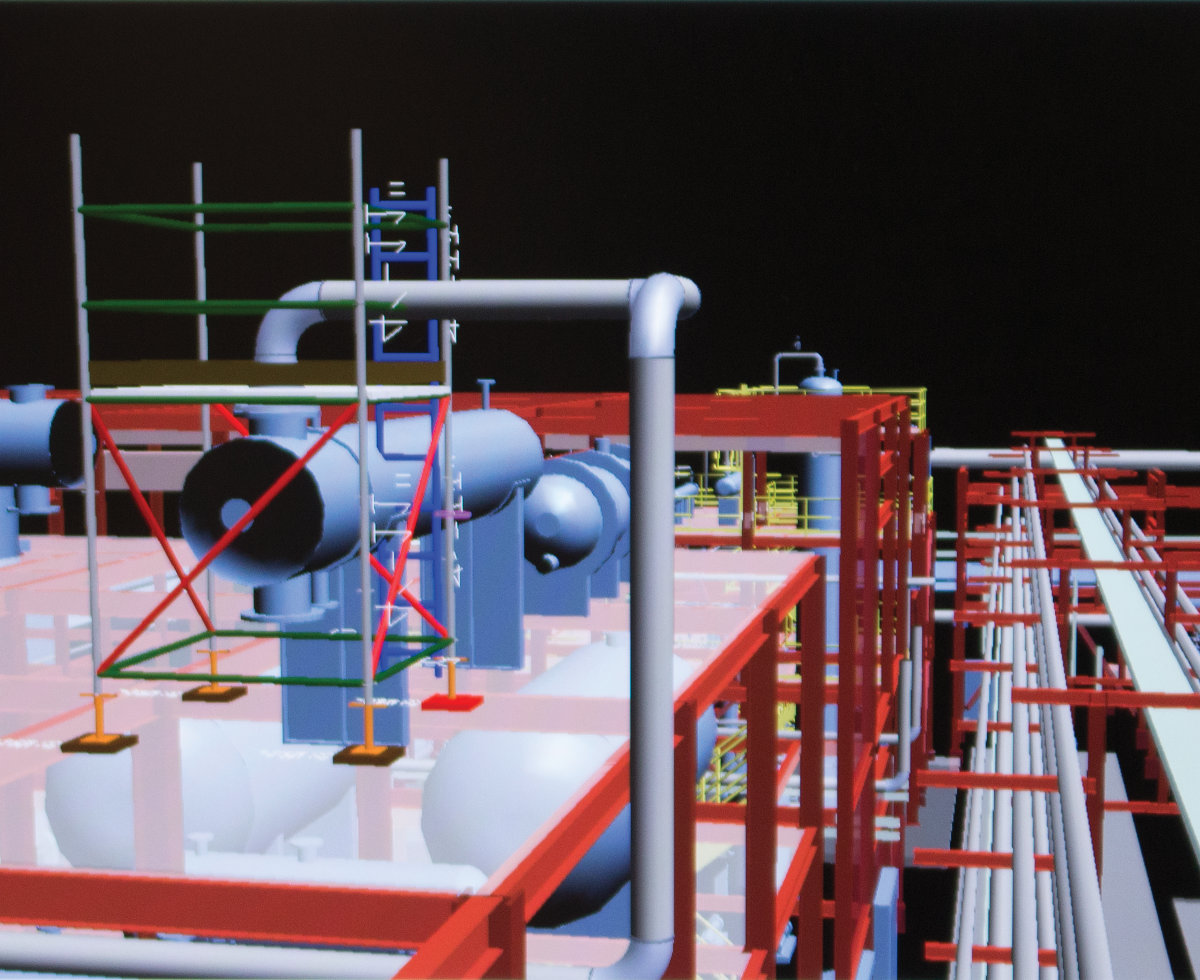

SGB BrandSafway has developed a unique multi-product approach to the provision of access on each industrial services project, giving our customers an optimised total access solution. Based on your project requirements, rather than our catalogue, we develop a bespoke access plan built on the most appropriate access solution for each elevation from traditional or systemised scaffolding to mechanical access or rope access - all from one supplier.

SGB BrandSafway's years’ of experience in the disassembly, reassembly and renewal of industrial insulation pipes, vessels, tank walls and specials, have helped clients on some of the world’s largest new construction, renovation and maintenance shutdown projects.

From our regional support centres, or directly on site, we can offer insulation services either independently or as part of a multi-disciplined approach. Meeting your schedule, budget and working to the highest health and safety standards are all part of our solution. We can also take care of the analysis, consulting, planning, materials, performance and quality.

SGB BrandSafway’s specialist surface preparation and protective coatings teams work to extremely exacting standards, using the latest technology to deliver advanced solutions to our customers. Our painting and coating solutions are not only available on site, but can be carried out in a controlled environment at our premises to avoid disruption to your operations.

Our multi-disciplinary approach enables us to coordinate the different disciplines and activities properly so that a maintenance programme will run according to plan.

Our focus at SGB BrandSafway is increasingly on digitization, aimed specifically at simplifying work processes and offering transparency to contracting parties. New applications are always being developed to support processes throughout the supply chain, from onboarding to invoicing and after-services.

In accordance with our customer we prepare detailed work plans, which focus on a clear schedule and pay extra attention to the storage of materials and the logistics on site. We are continuously observing our processes so we can work more efficiently.

Collaboration is the key to our mutual success. Working together, we strive for leadership in the field of safety and by providing detailed work plans, aim to deliver the most effective and productive safety solution to your project requirements.